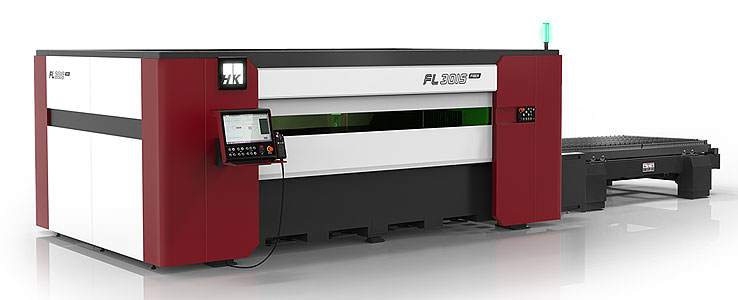

Laser Cutting Machine Trumpf

Typical materials used in flame cutting, or oxygen cutting / Oxyfuel, are low-alloy steel, also referred to as mild steel stainless or aluminum, and cast irons.

A laser generator can be described as a component that produces a beam. Fiber laser generators are suitable for all types sheet metals and tubes. CO2 lasers can be used to produce wood, plastic, acrylic and leather.